40 Ton Closed Circuit Counter Flow GTM-10 Supedyma Water Cooling Tower Manufacturer Cooling System For The Aircompressor

| Packaging: | Standard packing ensures proper protection during transportation |

|---|---|

| Brand: | SANJIU |

| Place of Origin: | Jiangsu, China (Mainland) |

Basic Info

Model No.: GTM-10

Product Description

GTM Series Counter Flow Closed Water Cooling Tower

GTM Series have been developed since 2011, with capacities ranging from 5 to 250 tons/ unit/ hour. This series is finished with alloy (Mg-Al-Zn) coated steel, or stainless steel enclosure, stainless steel or copper heat exchange coils. Besides, this series can be integrated with circulating pumps and valves on options.

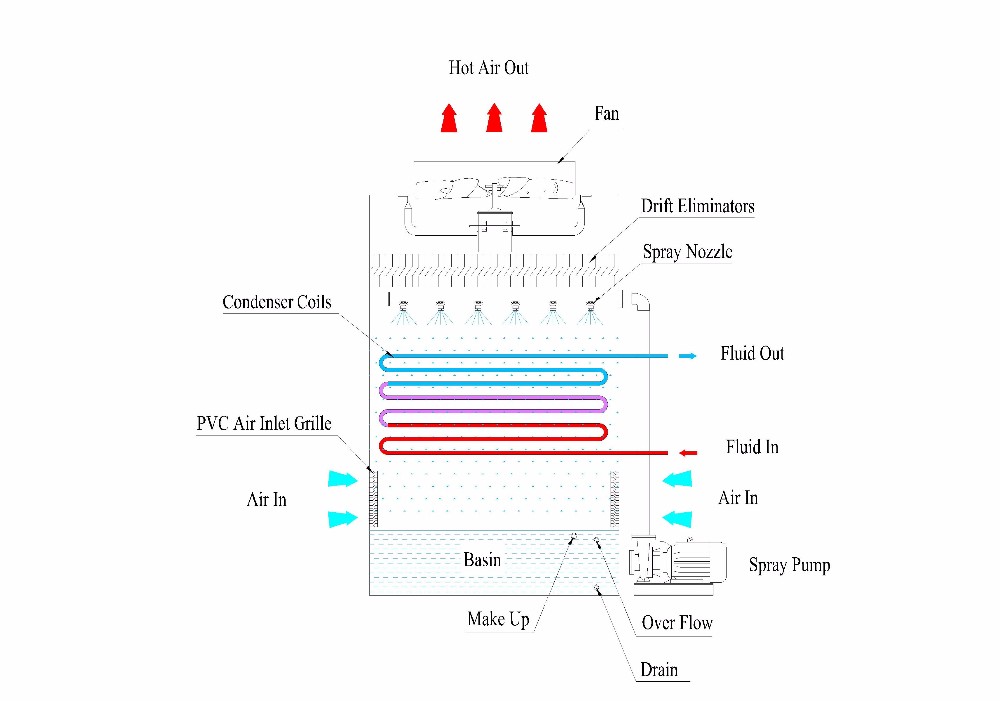

As counter flow towers, the cool air is inlet through both sides of the tower from the bottom, then drawn upwards through the whole heat exchange coils, against the spraying water in the opposite direction, eventually outlet with heat.

GTM Towers tend to be more compact, taking less installation space. And it’s without PVC filling stuff, more suitable to cool hot water of higher temperature. This series are also widely applied in different fields, to provide circulating cooling water or other liquid for HAVC system, air compressors, melting shops, heating machines, chemical plants, and food industries etc.

40 Ton Closed Circuit Counter Flow GTM-10 Supedyma Water Cooling Tower Manufacturer Cooling System For The Aircompressor

Note: All the data is under the condition of 28℃ wet temperature.

If any change of condition,the data will change.

|

Model no. | GTM-10 (closed circuit) | |

Water flow rate | 40 m³/h, adjustable as different temperature | |

Cooling capacity | From 65~55℃to45~35℃ | |

Water pressure | 0.32Mpa | |

Pipe diameter | Input diameter(mm) | DN100 |

Output diameter(mm) | DN100 | |

Rated Power | Fan (KW) | 1.5x2 |

Spray pump(KW) | 2.2 | |

Material of shell/tower body | Superdyma(imported from Japan) | |

Material of tupe | SUS304;Red copper | |

Installation Method | Modular Design,Easy Install | |

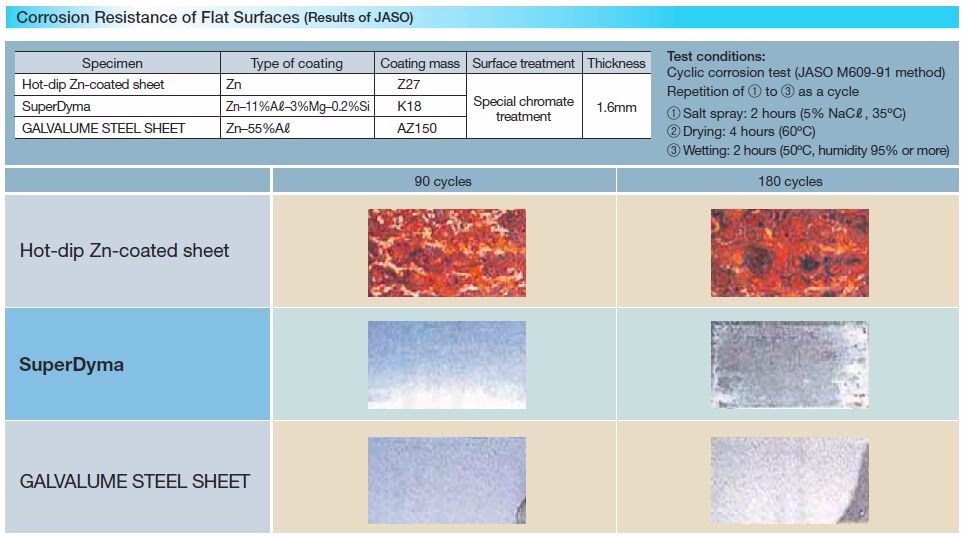

Closed water cooling tower shell is made in Mg-Al-Zn alloy coated steel, of "SuperDyma" series from company Nippon Steel, originally imported Japan. This special alloy coated steel is much better than galvanized steel in corrosion proof performance

-Quick response in 12 hours

-Professional and economical cooling solution for every client

-Considerate and complete after sales service

Below information are normally required to know for selection of a most proper tower model and solution:

| Application: | (Explanations: Where the cooling towers will be used for? e.g. for HAVC system, Air Compressors, Melting Furnaces, etc.) | |||

| * Water Flow Rate: | m³/h | (Explanations: How many Tons of water required per hour?) | ||

| * Inlet Water Temp.: | °C | (Explanations: Temperature of hot water to be cooled) | (also descriped as "water temperature drop") | |

| * Outlet Water Temp.: | °C | (Explanations: Temperature of cooled water, usually it shall be at least 3~4 °C higher than the wet-bulb temp.) | ||

| * Wet-bulb Temp.: | °C | (Explanations: Highest wet bulb temp. of the location/area or city to install the tower is essential to know to evaluate the size of towers) | ||

| * Power Supply: | (Explanations: 380V/3 Phases is standard, which we could have in stock, but for customized towers, the delivery time could be longer) | |||

For easier discussions, 24 hours on line service available: Angela is online: skype: oasanjiu Mob./WhatsApp: 13559666650

Many thanks for your interests, and your inquires are always well attended!

Contact us if you need more details on Cooling System for the Aircompressor. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Cooling Tower Manufacturer、Superdyma. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Closed Circuit Counter Flow Cooling Tower