136 Ton Steel Open Cooling Tower for Commercial Building HVAC System

| Packaging: | Standard packing ensures proper protection during transportation |

|---|---|

| Brand: | SANJIU |

| Place of Origin: | Jiangsu, China (Mainland) |

Basic Info

Model No.: GOM Series

Product Description

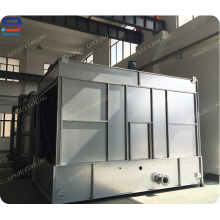

136 Ton Steel Open Cooling Tower for Commercial Building HVAC System

Note: All the data is under the condition of 25.5℃ wet temperature.

If any change of condition,the data will change.

|

Model No. | GOM 0109S-1 | |

Nominal Flow Rate | 136 m³/h, adjustable as different temperature | |

Cooling Range | From 65~55℃to45~35℃ | |

Pipe diameter | Input diameter(mm) | DN150*2 |

Output diameter(mm) | DN150 | |

Rated Power | Fan (KW) | 3.7 |

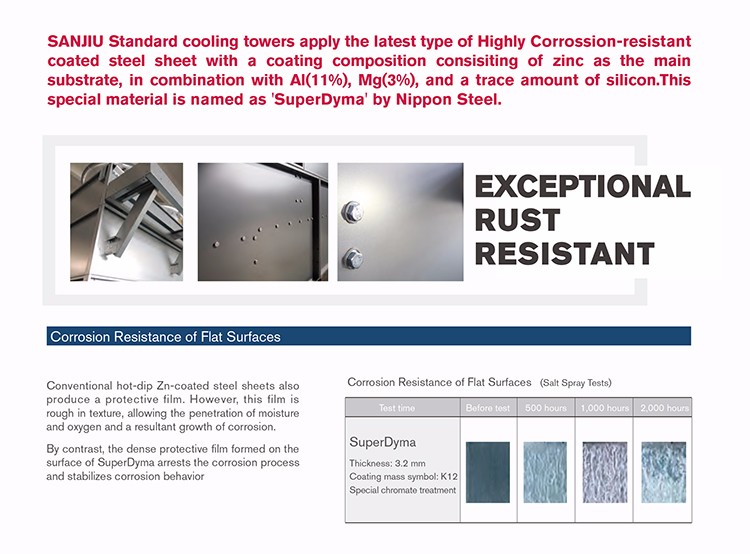

Material of shell/tower body | Superdyma(imported from Japan) | |

Fill Material | MX-75 PVC | |

Installation Method | Modular Design,Easy Install | |

STRUCTURE & CASING

The tower enclosure is made in special alloy (Mg-Al-Zn) coated steel panels, originally imported from Nippon Steel or Posco. These panels exhibit superior corrosion resistance, and self-heal when scratched during the service period. The panels are bolted and sealed for water tightness. The casing is complete with maintenance access doors for internal inspection convenience.

DRIFT ELIMINATORS

The Drift Eliminator is vacuum formed from PVC sheets into a special shape allowing minimum water carry-over, with negligible pressure drop. The eliminator is formed by sections that can be easily handled.

AXIAL FAN SECTION

The axial fans have light weight al-alloy blades perfectly balanced and coupled to a weather proof electric motor. The fan casing is a steel cylinder to draw the air vertically and avoid the risk of recirculation. The tip speed of the impeller is limited to keep the noise level within acceptable limits.

WET DECK FILL

The fill is formed inflame-retardant PVC sheets with a shape specially designed to optimise the turbulence of the counter current fluids. For medium fouled waters we can supply a fill with enlarged grids. All the raw materials are of virgin grade from approved suppliers.

WATER DISTRIBUTIONSYSTEM

The main header(s) - one to three depending on the model - is fabricated in steel and hot dip galvanized. Secondary headers are made in PVC and use non-clogging spray nozzles in special rubber compound or in resin, depending on the model.

WATER BASIN

Water basin is constructed in the same alloy coated steel, for the collection of cooled water, complete with:

- water outlet with an easily accessible filter,

- drain and overflow connections,

- make up water connection complete with float valve,

- air inlet and wind protective grids in PP honeycomb, with low pressure drop.

- bleed off pipe with regulating valve to prevent salt concentration in water.

FINISH

The standard Cooling Tower is delivered in alloy coated steel finish without any additional painting, unless other color is ordered as an optional item.

-Quick response in 12 hours

-Professional and economical cooling solution for every client

-Top Cost Performance in Worldwide

Below information are normally required to know for selection of a most proper tower model and solution:

| Application: | (Explanations: Where the cooling towers will be used for? e.g. for HAVC system, Air Compressors, Melting Furnaces, etc.) | |||

| * Water Flow Rate: | m³/h | (Explanations: How many Tons of water required per hour?) | ||

| * Inlet Water Temp.: | °C | (Explanations: Temperature of hot water to be cooled) | (also descriped as "water temperature drop") | |

| * Outlet Water Temp.: | °C | (Explanations: Temperature of cooled water, usually it shall be at least 3~4 °C higher than the wet-bulb temp.) | ||

| * Ambient Temp.: | °C | (Explanations: Highest wet ambient temp. of the location/area or city to install the tower is essential to know to evaluate the size of towers) | ||

| * Power Supply: | (Explanations: 380V/3 Phases is standard, which we could have in stock, but for customized towers, the delivery time could be longer) | |||

For easier discussions, 24 hours on line service available: Angela is online: skype: oasanjiu Mob./WhatsApp: 13559666650

Many thanks for your interests, and your inquires are always well attended!

Contact us if you need more details on Steel Open Cooling Tower for Commercial Building. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Building Cooling Towers、Cooling Tower. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Steel Open Cooling Tower

Premium Related Products